Conveying And Drying Food Chain Mesh Conveyor Belt For Construction

Chain Mesh Conveyor Belt Advantage:

With acid, alkali, wear and low, high temperature characteristics;

With good transport function, resistance to fracture and oxidation;

Professional design and compact shape, easy to install and run smoothly without deformation;

Cold resistance at negative moderate high temperatures. Conveyor belts have many advantages that increase productivity, help control costs and improve overall product quality, including:

• Largest available mesh area-up to 86%

• Easy to clean, clean-in-place design

• Non-slip, active transmission

• Very low belt quality

• Minimum diameter end roller and drive roller

• Active transmission for precise tracking

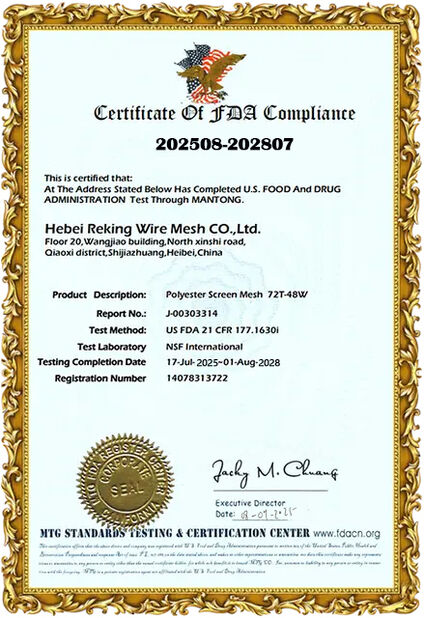

• FDA approved

Material: carbon steel, galvanized iron wire, spring steel wire, corrosion-resistant and high-temperature-resistant stainless steel materials (304, 310, 310S, 314, 316, 316L, 430, etc.) 304 stainless steel 1Cr18Ni9Ti stainless steel 0Cr18Ni14NO2CU2 heat-resistant acid-resistant steel

Chain Mesh Conveyor Belt Classification:

Assembly line metal transmission mesh belt, heat treatment furnace high temperature resistance mesh belt; stainless steel mesh belt; conveyor mesh belt; tunnel kiln mesh belt; Great Wall mesh belt; drying mesh belt; painting equipment mesh belt; spraying equipment mesh belt; cleaning machine Mesh belt; food mesh belt; food cleaning and conveying chain plate; stainless steel chain plate; herringbone mesh belt; double-rotation energy-saving mesh belt; fuel injection cooling mesh belt; B-shaped mesh belt; baffle conveyor belt; chain conveyor belt; fruit and vegetable cleaning Mesh belts; quick-freezer chain nets; single-freezer chain nets; quick-freezing horseshoe-type net chains; special conveyor chain nets for vegetable dehydration line equipment.

Chain Mesh Conveyor Precautions:

Stainless steel mesh belts have a wide range of applications, so what should be paid attention to when maintaining food-grade stainless steel mesh belts. The general method of wiping, cleaning, lubricating and adjusting stainless steel mesh belts to maintain and protect the performance and technical conditions of construction machinery is called equipment maintenance. The main maintenance requirements for food-grade stainless steel mesh belts are:

(1) clean the sliding surfaces, screws, racks, gearboxes, oil holes, etc. of stainless steel mesh belts, free of oil, oil, or gas leakage from all parts of the equipment, and chips around Debris and dust. Mechanical engineers should clean them;

(2) Neatly place tools, accessories and workpieces (products), and organize the pipeline.

(3) Lubrication or timely oil change, continuous oil injection, no dry friction, normal oil pressure, varnish standard, smooth oil road, oil quality meets requirements, oil cup, linoleum clean;

(4) safety follow safety operation regulations, do not use Overloaded equipment eliminates unsafe factors in a timely manner. The maintenance of food stainless steel conveyor belt generally includes daily maintenance, regular maintenance, regular inspection and accuracy check. Maintenance of equipment lubrication and cooling systems is also an important part of equipment maintenance.

Chain Mesh Conveyor Belt List

|

Product Name

|

Conveying And Drying Food Chain Mesh Conveyor Belt For Construction

|

|

Material

|

stainless steel or others

|

|

Grade

|

SUS201, SUS304, SUS316, A2-70, A2-80, A4-80, 4.8 6.8 8.8 10.9 12.9

|

|

Size

|

as cutomized or required

|

|

Used

|

conveyor belt system machines

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!