750AB Industrial Polypropylene Filter Cloth Acid And Alkali Resistant Filter Press Filter Cloth

| Product name: |

High Tension Soild-Liqiud Separation Filter Cloth For Juice Extractor |

| Working temperature |

Not more than 280 degree |

| Air Permeability |

50-1000CFM |

| Length |

Customzied |

| Width |

Customized |

| Usage |

Mining and metallurgy, Chemical industry, Food and beverages, Pharmaceuticals and bioengineering

|

Feature:

Precision filtration accuracy:

It offers multiple filtration accuracy grades ranging from 1 micron to 2000 microns, allowing for precise selection based on the particle size distribution of the target particles. This effectively intercepts impurities and ensures the clarity of the filtrate or the purity of the solid phase.

Outstanding permeability and high throughput:

The unique fabric structure design ensures excellent penetration performance even under high filtration accuracy, with fast filtration speed and large flux per unit area, significantly improving production efficiency.

Excellent mechanical strength and dimensional stability:

It features high tensile strength, tear resistance and wear resistance, capable of withstanding mechanical pressure, friction and stretching during the filtration process. It has a long service life and is not prone to deformation or damage.

Outstanding resistance to chemical corrosion:

Depending on different materials (such as polyester, polypropylene, nylon, PTFE, etc.), it can withstand the erosion of various chemical substances like acids, alkalis, and organic solvents, and is suitable for harsh chemical filtration environments.

Good slag unloading performance:

The surface is smooth, the fiber structure is stable, and solids will form a uniform filter cake on the surface. It is easy to peel off during unloading, convenient to clean, and reduces maintenance downtime.

Application:

Mining and metallurgy: Used for dewatering of concentrates and tailings in concentrators, filtration of leachates in hydrometallurgy, purification of electrolytes, etc. (such as filter cloths for plate and frame filter presses and belt filter presses).

Chemical industry: Product recovery, catalyst separation and mother liquor filtration in the production processes of pigments, dyes, fertilizers, resins, pesticides, etc.

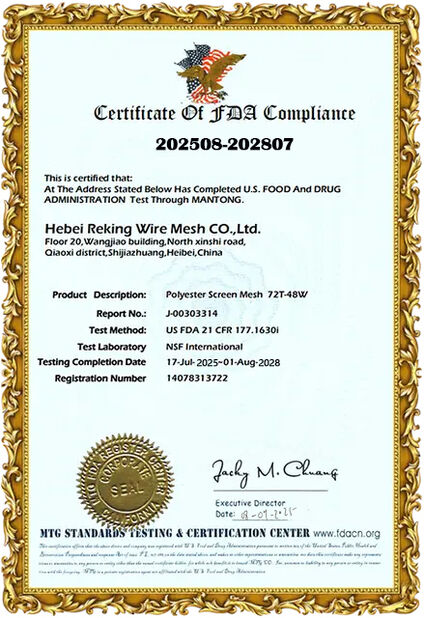

Food and beverages: Clarification and filtration of syrups, fruit juices, edible oils, alcoholic beverages, and starch to ensure product safety and hygiene (meeting food-grade standards such as FDA).

Pharmaceuticals and bioengineering: Sterilization, clarification and collection of active ingredients for antibiotics, fermentation broth and traditional Chinese medicine extracts, with the requirement of being pollution-free, easy to clean and sterilize.

Environmental protection water treatment: Sludge dewatering for urban sewage and industrial wastewater (such as filter cloth for centrifuges and screw presses), as well as pretreatment of industrial water.

Other fields: solid-liquid separation in the production processes of ceramic glazes, magnetic materials, titanium dioxide, electroplating solutions, etc

How to Choose a Suitable Filter Cloth:

Filter material: Select corrosion-resistant fiber materials (such as PP resistant to strong acids and PET resistant to weak acids) based on the chemical properties of the filter material (acidity, alkalinity, corrosiveness).

Fabric structure: Select plain weave, twill weave or satin weave based on the characteristics of the particles. Plain weave has good interception performance, while satin weave has good cake removal performance.

Filtration accuracy: Select the matching pore size based on the size of the target particles to be retained. It is not the case that the finer the better; a balance between accuracy and flow rate is necessary.

Mechanical properties: Select filter cloth with corresponding tensile and wear resistance strength based on the type of filtration equipment used (filter press, centrifuge, vacuum filter) and working pressure.

Service:

Professional technical consultation: Our experienced team is here to solve your filtration problems.

Sample testing: Provide samples for on-machine testing to verify the filtration effect.

Customized production: Supports customization for non-standard sizes, interfaces and special performance requirements.

Fast delivery: Abundant inventory and efficient production lines ensure a prompt response to your needs.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!