Food Grade 304 1.2m wide 1.5m wide 1.8m wide Stainless Steel Chain Link Spiral Wire Mesh Conveyor Belt

Stainless steel chain conveyor is a robust material handling system designed to transport products, components, or materials along a defined path. It consists of interlinked stainless steel chains (often roller chains, flat-top chains, or modular plastic belts on stainless frames) that form a continuous loop driven by sprockets. The chains run on stainless steel tracks or guides, supported by a rigid stainless steel frame. Key features include high strength, corrosion resistance, and suitability for demanding environments.

| Material |

SS304, SS316, SS316L, SS430, Galvanized wire, customized |

| Spiral wire diameter |

0.5mm - 3mm, customized |

| Rod wire diameter |

0.5mm - 4mm, customized |

| Spiral pitch |

5-50mm, customized |

| Rod pitch |

5-50mm, customized |

| Wide |

Mesh belt wide (without chain)/ Conveyor belt wide ( with chain ) |

| Length |

1m - 10m, customized |

Advantages:

1. Superior Corrosion Resistance: Resists rust, chemicals, water, steam, and cleaning agents, making it ideal for wet, humid, or corrosive environments (food, chemical, marine).

2. High Hygiene & Cleanability: Smooth, non-porous surfaces prevent bacterial growth and allow for easy. Essential for food, beverage, pharmaceutical, and medical applications.

3. High Temperature Resistance: Maintains strength and integrity under significant heat (e.g., ovens, washers, sterilizers, foundries).

4. Strength & Durability: Withstands heavy loads, impacts, and abrasive materials better than many alternatives. Long service life.

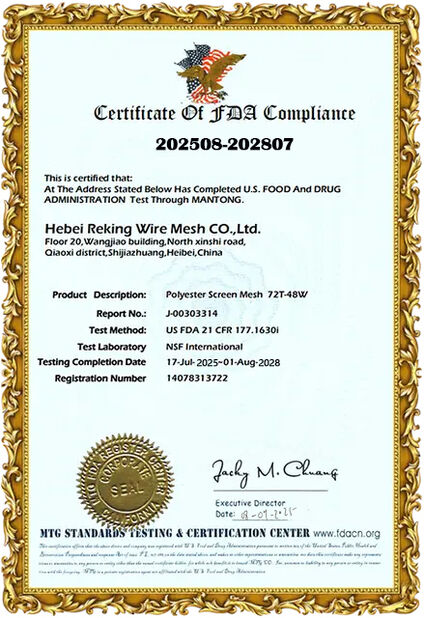

5. Sanitary Design: Minimizes areas where debris can accumulate, meeting strict sanitary regulations (FDA, USDA, 3-A).

6. Aesthetic Appeal: Maintains a clean, professional appearance over time.

7. Resistance to Oxidation & Staining: Performs well outdoors or in atmospheres prone to oxidation.

How to use it:

1. Installation: Securely mount the rigid frame, ensuring proper alignment and leveling. Install drive unit (motor, gearbox) and tail/take-up section.

2. Chain Tensioning:Correctly tension the chain using the take-up mechanism – not too tight (excessive wear) or too loose (slippage, derailment).

3. Loading:Products are typically loaded onto the chain surface manually, via feeders, or from preceding equipment. Ensure load is within capacity and evenly distributed.

4. Operation: Start the drive system. Chains move continuously or index (start/stop) along the track, carrying the product. Speed is controlled via the drive.

5. Unloading: Products are offloaded at the end (or intermediate points via pushers/diversions) manually, by gravity, or onto another conveyor.

Cleaning & Maintenance:

Regular Cleaning: Use water, steam, or approved sanitizers. High-pressure wash is common. Ensure proper drainage.

Lubrication: Use food-grade or compatible lubricants sparingly if required (some designs use self-lubricating chains or run dry). Avoid contamination.

Inspection: Regularly check for chain wear (stretch), damaged links, worn sprockets, proper tension, bearing condition, and frame integrity.

Component Replacement: Replace worn chains, sprockets, guides, and bearings promptly to prevent failures.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!