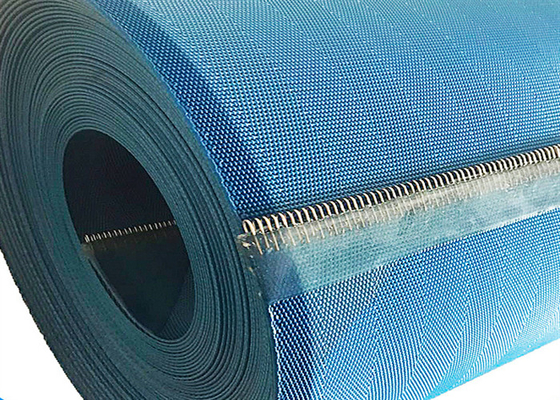

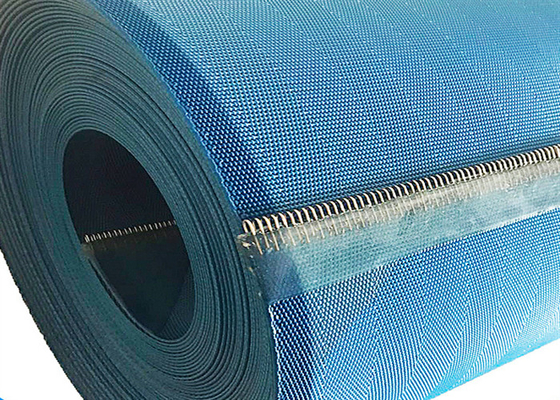

Conveyor Belt Polyester Sludge Dewatering Belt For Food Grade And Industrial Grade

Polyester Sludge Dewatering Belt Introduction

The polyester sludge dewatering belt are also called Press- Filter Fabrics

which is mainly used for sludge dehydration, pulp and juice squeeze mine smelting

mine tailings drying and other pressure filtration industries

Polyester Sludge dehydration mesh belt have the characteristics of good water permeability

air permeability and non-revealed sludge, acid-resisting and alkali-resisting. Because of their designing structure

the sludge can be peel off easily from the filter cake so the screen are easily cleaned and have a long working time

Mainly matching with belt type filter press, vacuum rubber belt filter and vacuum horizontal belt filter

Polyester Sludge Dewatering Belt Features

| Model |

Wire Diameter |

Density Root/10cm |

Air Permeability m3/m2h |

Net Weight g/m2 |

Strength kg/cm |

Used in |

| Wrap |

Weft |

Wrap |

Weft |

| 14803 |

0.7 |

0.8 |

142 |

47-60 |

3900-8500 |

1400 |

240 |

Sludge,Squeeze juice |

| 16803 |

0.7 |

0.8 |

156 |

46-50 |

6000 |

1400 |

265 |

Sludge,Squeeze juice |

| 16904 |

0.75 |

0.9 |

156 |

47 |

8000 |

1800 |

280 |

Iron and steel industry sludge dewatering Living slude dewatering |

| 121054 |

0.9 |

1.05 |

120 |

42 |

8000 |

1650 |

340 |

Iron and steel industry sludge dewatering |

| 22903 |

0.5 |

0.9 |

220 |

50-55 |

9000 |

1200 |

200 |

Living slude dewatering |

| 20703 |

0.5 |

0.7 |

200 |

70 |

10000 |

1000 |

185 |

Living slude dewatering |

| 24504 |

0.5 |

0.5 |

240 |

130-140 |

8500 |

1180 |

220 |

Paper dry network |

| 8903 |

0.9 |

0.9 |

78 |

50 |

8500 |

1430 |

210 |

industrial sludge dewatering |

| 16704 |

0.7 |

0.7 |

160 |

90 |

12000 |

1350 |

165 |

Building materials dewatering |

| 26908 |

0.5 |

0.9 |

26.4 |

69-75 |

5000 |

1364 |

240 |

Viscosit of the larger |

| 12 Mesh |

0.75 |

0.8 |

47 |

48 |

|

650 |

94 |

Paper pulp washing |

Polyester Sludge Dewatering Belt Advantage

1 Good permeability air permeability

2 Non-revealed sludge

3 Acid-resisting alkali-resisting heat resistance(180 °C)

4 Because of their designing structure, the sludge can be peel off easily after pigeonhole filter

so the screen are easily cleaned and have a long working time

5 Therefore they are designed specially for sludge dehydration

6 To make the culture paper, printing paper, and packing paper

7 Filled or unfilled to achieve different filtration characteristics

Polyester Sludge Dewatering Belt Date Sheet

| Weaving Type |

Model |

Thread Diameter (mm)

|

Air Permeability

(m3/m2h)

|

| Warp |

Weft |

filled with stuff |

| Large Loop |

4070 |

0.9 |

1.1 |

0.9x4 |

20000x500 |

| 0.9x5 |

| Medium Loop |

3868 |

0.7 |

0.9 |

0.8x3 |

18500x500 |

| 0.8x4 |

| Small Loop |

3252 |

0.52 |

0.7 |

0.68x3 |

15000x500 |

Polyester Sludge Dewatering Belt Advantage Packing detail

- Wooden case is the best for ocean shipment because it can effective avoid the damage during shipping

- There also have some customer request us to use the carton to packing their goods can be shiped by courier by air and by sea

- We can according to customer's requirement

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!